熱間工具鋼

熱間工具鋼の特性と用途

熱間工具鋼は、高温環境向けに特別に設計された工具鋼の一種で、高温、熱応力、熱下での摩耗に耐える必要がある工具や金型の製造に使用されます。高温でも良好な硬度、靭性、耐熱疲労性、耐酸化性を維持できることが特徴です。

熱間工具鋼の特性

耐高温性: 熱間工具鋼は、硬度や強度などの機械的特性を高温でも維持できます。一般的に 500°C ~ 700°C の温度範囲で良好な性能を発揮しますが、一部の上級グレードはさらに高い温度でも使用できます。

熱疲労耐性熱間加工鋼は熱疲労に対する優れた耐性を備えており、加熱と冷却の繰り返しサイクルに耐えることができ、熱ストレスによる割れや破損のリスクを軽減します。

耐酸化性熱間加工鋼は通常、酸化に対する耐性が優れており、高温での表面腐食に効果的に耐えます。

高い強度と硬度熱間工具鋼は高い強度と硬度を示し、高温でもこれらの特性を維持するため、材料が高圧や衝撃を受ける用途に適しています。

優れた靭性: 熱間加工鋼は、高い強度にもかかわらず、一般に優れた靭性を維持し、高温条件下での脆性破壊を防ぐのに役立ちます。

耐摩耗性熱間工具鋼は耐摩耗性に優れているため、高温条件下での大きな摩耗に耐える工具に最適です。

良好な加工性熱間加工鋼は、適切な熱処理により優れた機械的特性を実現し、長期にわたる過酷な作業にも耐えることができます。

熱間工具鋼の一般的な種類

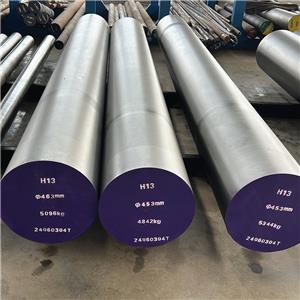

Hシリーズ(例:H13鋼):

特徴H シリーズ鋼は耐熱性と耐摩耗性に優れており、耐熱疲労性に優れているため、高温、高負荷用途に特に適しております。

アプリケーション: 鋳造金型、鍛造金型、押し出し金型などによく使用されます。

Pシリーズ(例:P20スチール):

特徴: プラスチック成形や低温熱間加工用途に適しており、良好な加工性と適度な耐熱性を備えています。

アプリケーション: プラスチック金型、ダイカスト金型などに使用されます。

Sシリーズ(例:S7 鋼鉄):

特徴: 優れた耐衝撃性と耐摩耗性で知られており、高温条件下での重作業工具に最適です。

アプリケーション: 鋳造金型、衝撃工具、打ち抜き工具などに広く使用されています。

Vシリーズ(例:V10 鋼鉄):

特徴: 耐摩耗性、耐高温酸化性に優れており、高温作業工具に適しています。

アプリケーション: 鋳造金型、冶金金型、ダイカスト金型などの製造に使用されます。

熱間工具鋼の主な用途

熱間工具鋼の高温特性により、次のような熱を伴う用途に特に適しています。

鋳造用鋳型熱間加工鋼は、高温に耐え、優れた耐摩耗性を維持できるため、鋳造業界で広く使用されており、特にアルミニウムや銅などの金属を鋳造する際に使用する金型に使用されています。

鍛造金型: 金属鍛造プロセスで使用される鍛造金型は、高温と繰り返しの熱応力に耐える必要があるため、熱間加工鋼はこれらの用途に非常に有利です。

ダイカスト金型熱間加工鋼は、ダイカスト金型の製造、特にアルミニウム、亜鉛、その他の金属を使用する用途で広く使用されています。

冶金ツール冶金業界では、熱間加工鋼は鋼塊鋳型、ロール、熱処理工具などさまざまな工具の製造に使用されます。

熱間せん断工具: 熱間加工用鋼は、耐酸化性と耐摩耗性が高く、切断金型や打ち抜き工具などの熱間せん断工具に最適です。

熱間押し出し成形金型熱間加工鋼は、優れた靭性を維持しながら高温と大きな衝撃荷重に耐えることができるため、熱間押し出しプロセスで広く使用されています。

その他の高温用途熱間工具鋼は、炉、熱処理装置、高温圧力容器などの高温環境でも使用されます。

まとめ

熱間工具鋼は、優れた高温性能、耐熱疲労性、耐酸化性、靭性を備えており、高温工具や金型の製造に広く使用されています。主に鋳造、鍛造、ダイカスト、その他の高温作業を伴う産業で使用されています。適切な熱処理を施すことで、熱間工具鋼は高温でも優れた特性を維持し、過酷な作業条件でも長期にわたって安定した性能を発揮します。